Rocket propellants are the chemical (or physical) substances that produce the high-speed gases necessary to propel rockets. Different propellants balance thrust, efficiency, storability, cost and safety — and that balance determines whether a fuel is used in a fighter missile, a reusable orbital launcher, or a deep-space probe.

In this article, we will cover the major categories of propellants, the tradeoffs engineers consider, and why certain missions favor one fuel over another.

The Main Types of Rocket Fuel

Some rocket systems pack the fuel and oxidizer together in a single solid grain that burns from the surface outward, delivering powerful, immediate thrust; others keep fuel and oxidizer separate as liquids that are fed into a chamber, allowing engineers to throttle, stop, and restart the engine as needed. There are also hybrid designs that mix a solid fuel with a liquid or gaseous oxidizer, monopropellant systems that rely on a single substance chemically decomposing over a catalyst, and non-chemical options such as electric or nuclear-driven concepts that use inert propellants or reactor heat to produce very efficient, low-thrust propulsion suitable for long-duration missions.

Each category brings its own tradeoffs in performance, complexity, storability and operational risk. So, let’s compare them.

Solid Propellants

- What: Fuel and oxidizer mixed into a solid grain (binders + oxidizer + powdered metal sometimes).

- Strengths: Simple storage, robust, high thrust at ignition, reliable (good for boosters and military rockets).

- Weaknesses: Once ignited you can’t throttle or easily shut down; lower specific impulse than best liquid combos; combustion stability can be tricky.

- Typical use: Booster stages, missiles, some sounding rockets.

China’s Long March 11 is an example of a modern, four-stage solid-propellant orbital launcher designed for quick response launches.

The Space Shuttle’s pair of Solid Rocket Boosters (SRBs) were large ammonium-perchlorate composite motors that provided most of the thrust at liftoff.

Europe’s Ariane 5 relied on two very large solid boosters for first-stage thrust.

The European Vega launcher used a solid P80 first stage (and other solid upper stages) in its configuration.

Liquid Bipropellants

- What: Separate liquid fuel and oxidizer fed to a combustion chamber (turbopumps or pressure-fed).

- Categories:

- Cryogenic (e.g., liquid hydrogen LH₂ + liquid oxygen LOX): very high specific impulse but requires very cold temperatures and insulation.

- Kerosene-type (RP-1) + LOX: denser, easier to store than LH₂, good for first stages (higher density impulse).

- Methane + LOX: intermediate; cleaner combustion (less soot), attractive for reuse and in-situ refueling (e.g., Mars missions).

- Storable hypergolic (e.g., hydrazine derivatives + NTO): ignite on contact, store at room temp — used for orbital maneuvering and historical launchers.

- Strengths: Throttleable, restartable, high performance options.

- Weaknesses: Complexity (pumps, plumbing), cryogenics add operational cost.

SpaceX’s Falcon 9 uses nine Merlin engines on its first stage that burn refined kerosene (RP-1) with liquid oxygen (LOX), a dense, high-thrust combination that’s well suited to first-stage performance and rapid turnaround.

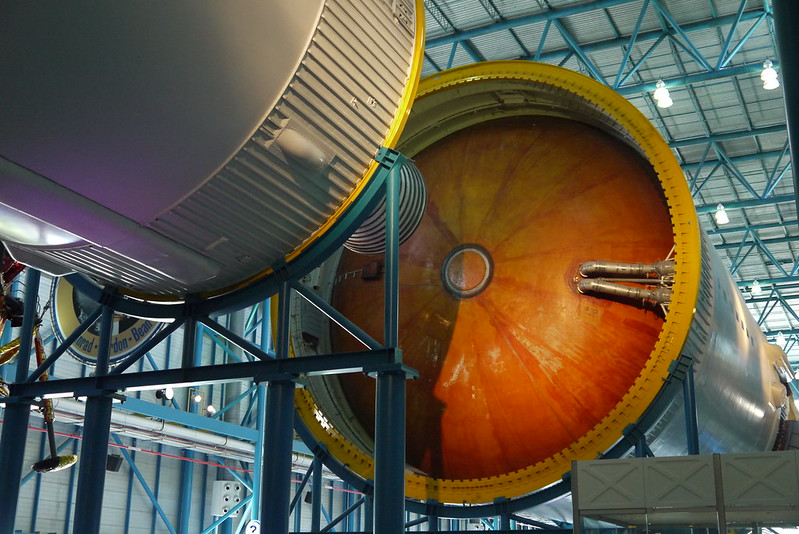

The Saturn V used liquid propellants throughout its stack: the huge first stage burned RP-1 with LOX for strong liftoff thrust, while the S-II and S-IVB upper stages switched to liquid hydrogen (LH₂) and LOX.

United Launch Alliance’s Delta IV family (including Delta IV Heavy) used large RS-68 engines burning LH₂ and LOX for very high thrust on cryogenic propellants.

Russia’s long-lived Soyuz launcher family employs RP-1 and LOX in its boosters and core stage, a reliable kerolox architecture that’s proven robust and inexpensive for routine orbital access.

Monopropellants

- What: Single fluid that decomposes (often via a catalyst) to produce hot gas and thrust (e.g., hydrazine historically, high-test hydrogen peroxide in some systems).

- Strengths: Simple feed systems, reliable for small thrusters, used for attitude control and orbital maneuvers.

- Weaknesses: Lower performance than bipropellants; many are toxic.

Hybrid rockets

- What: Solid fuel grain with a liquid or gaseous oxidizer (e.g., HTPB solid + nitrous oxide).

- Strengths: Simpler and safer than full liquids, can be throttled and shut down.

- Weaknesses: Challenging regression rate control and combustion efficiency; less mature for very large stages.

Gelled and advanced/novel fuels

- What: Gelled hydrocarbons or experimental propellants (ionic liquids, “green” monopropellants) that aim to combine storage safety and high performance.

- Status: Mostly R&D or niche; potential benefits in storability and reduced toxicity.

Non-chemical propulsion

- Electric propulsion (ion, Hall thrusters): use inert gases (xenon, krypton) as propellant; extremely high efficiency (Isp) but very low thrust — ideal for station-keeping and long, low-thrust missions.

- Nuclear thermal / nuclear electric: different physics (reactor heats propellant or generates electricity). High potential performance but major regulatory, political, and engineering challenges.

How engineers choose a propellant

When engineers pick a propellant they’re juggling a set of competing priorities rather than chasing a single “best” fuel.

At the heart of the decision is efficiency — specific impulse — because higher Isp means you get more thrust for each kilogram of propellant, which is crucial for upper stages and long missions; but efficiency doesn’t tell the whole story, because how dense a propellant is matters too: denser fuels like RP-1 shrink tank volume and structural mass even if their Isp is lower, so they can be better for heavy first stages.

Temperature and storability also shape choices: cryogenic combinations such as liquid hydrogen and oxygen offer great performance but demand insulation and boil-off management, whereas storable or hypergolic propellants trade some performance for easier handling and long-term readiness.

Equally practical are how a propellant ignites and whether it can be throttled or restarted — hypergolics simplify ignition and are reliable for maneuvering, while many liquid systems give throttle and restart flexibility but require pumps, plumbing and ignition systems.

Real-world constraints like toxicity, contamination and maintenance matter too: fuels that produce soot or corrosive byproducts shorten engine life and complicate reuse, and highly toxic propellants raise safety and environmental costs.

Finally, economical and logistical factors — existing supply chains, ground infrastructure, cost of handling, and even political or regulatory issues — often tip the balance; the best technical choice on paper can lose out to a cheaper, easier-to-support option when mission planners look at the full picture.

Examples of Rocket Fuel Combos

- RP-1 + LOX: dense, commonly used for first stages (good thrust/density tradeoff).

- LH₂ + LOX: very high Isp, used for high-performance upper stages.

- Methane + LOX: gaining popularity for reusability and ISRU prospects.

- Hypergolic (UDMH/Aerozine + NTO): used historically for orbital maneuvering and some launchers because of storability and ignition simplicity.

- Solid (AP-based composites): common in military and booster applications.